What is Reverse Engineering?

Reverse Engineering is used in different applications from jewellery design to copying existing products or software. In this article, Reverse Engineering is viewed through industrial perspective, where Reverse Engineering is reproduction of an existing physical part or component, without any engineering data such as 3D-models or technical drawings. The traditional process for product design is called Forward Engineering, where the model is designed from scratch using CAD-tools to produce the engineering data. Reverse engineering is sometimes also called as backward engineering or “physical to digital” process. [1]

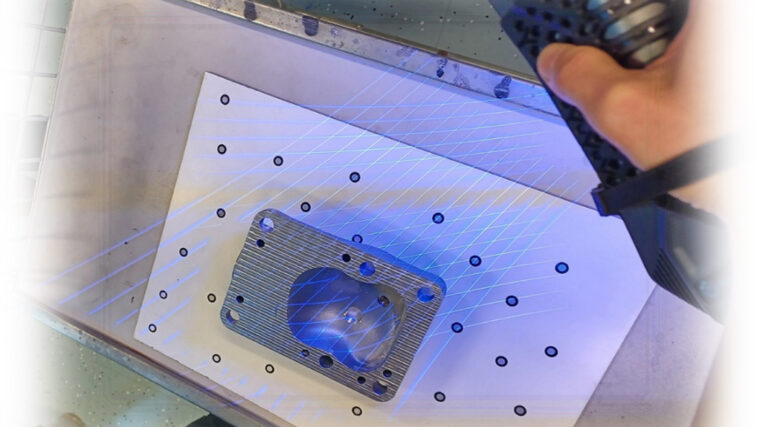

There are different ways to digitalize existing products and currently 3D-scanning is one of the most commonly used method. 3D-scanning has been used more than 30 years and the early development history of the method is in industrial metrological applications. Currently 3D-scanning is used to digitalize everything from people to aircrafts to historical artefacts. The future trend studies show growing interest in 3D-scanning also in consumer segment, where personalization of products becomes more common. [2]

Where 3D-scanning is used

In the Wohlers report 2022 future trends of 3D-scanning are listed, where visualization models are used in AR and VR applications. Nevertheless, 3D-scanning from industrial perspective, is more often used to inspect manufactured components such as welded structures, casted components and 3D-printed components. 3D-scanning as a tool for Quality control is not utilized very widely in Finnish manufacturing companies, even though there are good opportunities to compare manufactured parts to existing 3D-models in many machine workshops around the country.

3D-scanning is used to digitize existing components such as molds and to create digital spare parts. The challenge in creating digital spare parts is to transfer the scanned data to accurate solid 3D-model. Transferring the scanned data (point cloud) requires a high-performance computer and separate software that can handle the high amount of data collected. Using the 3D-scanners and processing the gathered data requires some special skills that need to be practiced to master the art of creating “digital twins”. [2,3]

Educational perspective

Reverse Engineering is not a “new thing”, but the easy-to-use user interface and price range of good quality scanners is making the technology more attractive all the time. For an industrial purpose, a bit more expensive laser scanners are needed, but for educational purposes the more affordable structured light scanners are a good entry to a world of Reverse Engineering. Nowadays there is even free 3D-scanning applications available to mobile devices and from my experience it doesn’t matter if you are learning new skills with such technologies that are not suitable for industrial use, the main thing is to learn by experimenting.

One of the most effective ways of learning new things is to get excited about the subject. When the students get excited about the possibilities of a new technology, such as 3D-scanning, they will learn more about the technology. It doesn’t matter if at first, they use their own mobile devices or devices sold for “hobby” use. When the students recognize the possibilities and limitations of the technology, it’s easier to dive into the deep end and start using the industry level equipment.

Training for professionals

As a university of applied sciences VAMK should be in the front line of introducing these technologies to student who can share their knowledge to the companies after graduation. We at VAMK are also providing training for the companies, where the training is either separately designed to meet the needs of the client or we are sharing our knowledge through different projects, such as Digital AM Technologies – From 3D Design to Manufacture. [4] The Digital AM Technologies project is financed from the appropriations of the REACT-EU instrument. The goal of the project is to prepare a training concept that raises the level of expertise in AM technologies and help the businesses to utilize these technologies in industrial production. More information about the project can be found from VAMK homepages: https://www.vamk.fi/en/hanke/digital-am-technologies. [5]

One good example of sharing the knowledge is a seminar arranged through Digital AM Technologies project on Friday afternoon, 24th of November. In this seminar Jussi Tammilehto from Tamspark Oy held a lecture about the basics of 3D-scanning. In this short afternoon seminar around ten employees from local companies attended the lecture. In this seminar the participants got a good overview of 3D-scanning, information what kind of devices are available in the market and the participants got also the opportunity to try 3D-scanning themselves. [3,5]