Used EV batteries are an environmental challenge because many battery materials are environmentally hazardous and you cannot discard the used battery without any measures to reuse, refurbish or recycle it. The concept of “second life” for electric vehicle (EV) lithium-ion batteries (LIB) refers to their use after they have reached the end of their useful life in an electric vehicle. While these batteries may no longer be suitable for powering vehicles, they still retain a significant amount of their capacity (approx. 80 %) and can be repurposed for other applications. The second life of EV batteries can offer business opportunities in the following ways:

Re-using the battery pack in an EV

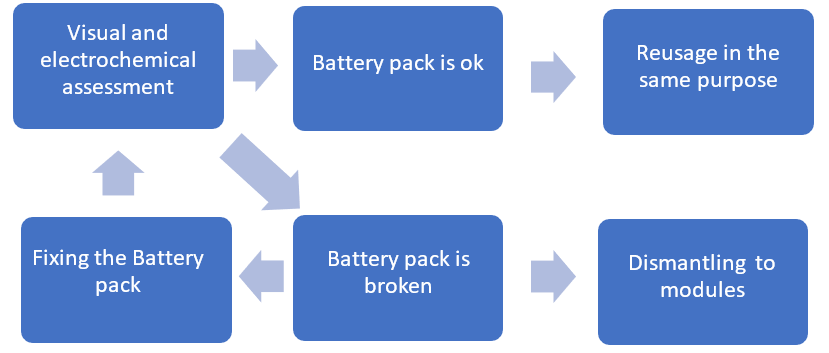

When the used LIB pack is acquired the first measure is to conduct a visual check of the battery; are there any leakage, bulking, cracks, or oxidation (rust). If there is visually observable damage on the battery it is most likely that it cannot be reused as such for the same purpose. In some cases, the battery pack can be fixed, but more likely it must be dismantled into the module level and the modules can be reused.

If the used battery pack passes the visual check and there are no issues with the mechanical integrity of the battery the next step is to conduct an electrochemical assessment of the battery by various measurements. This assessment can include measuring open circuit voltage (OCV), internal resistance, and the capacity of the battery. If the battery pack fails these tests it must be either fixed or dismantled into the modules. If the battery is fixable and the usage for the same purpose (EV) is considered, the battery must be profoundly retested after the battery repair and before the commissioning of the battery. (See Figure 1)

Repurpose the battery back for an energy storage

If the battery pack cannot be reused for some technical reasons for an EV it can be modified to be used as an energy storage system (ESS). This change into a stationary energy storage system usually requires modifications to the battery back and adjustments to the battery management system (BMS). In on-grid solutions also, an energy management system (EMS) is required to steer the battery operations either in electricity or power reserve markets. Also, in this scenario, the battery state of health (SOH) must be monitored and checked before commissioning for new usage. Safety evaluations are crucial concerns in all 2nd life battery solutions, and this implies especially when the battery is used in a new environment. The process is in this scenario pretty similar to the flow in Figure 1, the targeted usage is just different. In the following alternative, the battery pack has been evaluated to be unfixable and it has been dismantled into several battery modules.

Repurpose the modules for large-scale ESS

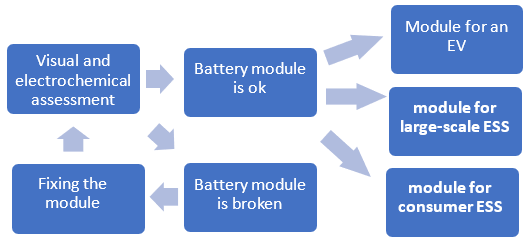

The dismantled battery module from the battery pack must go through a visual and electrochemical assessment and if the module is in order, it can be reused either in an EV or as energy storage either for a large- or consumer-scale ESS (see Figure 2.). Used EV battery modules can be changed into a large-scale ESS which balances the intermittent renewable energy sources by providing grid stabilization services. Second-life EV battery modules can also be employed in commercial and industrial settings to reduce electricity costs by peak shaving or load shifting. Both large- and consumer-scale ESS can store energy during low-demand periods and discharge it during peak-demand periods, minimizing electricity bills.

In remote locations without access to reliable electricity grids, second-life EV batteries can be used to create an off-grid power system for an electricity consumer. These off-grid energy systems are mostly relying on small-scale solar power, and they need a specific off-grid inverter. These systems can provide electricity for lighting, small appliances, and other low-power applications. They can be particularly beneficial in developing regions or during emergency situations where power infrastructure is limited. Repurposed EV battery modules can be utilized also with on-grid solutions as home energy storage units. They can store excess electricity generated from rooftop solar panels during the day and provide power during the evening or in case of a grid outage.

Restoring the battery module and reusing the battery cells

If the battery module’s visual and electrochemical assessment indicates that the battery module is out of order the situation can be a challenging one. If the reason for the module failure is in broken battery cells it can be too costly to replace the malfunctioning cells. If the cells of the module are intact there can be an opportunity to restore the battery module. Albeit it is very labour-intensive to test every individual battery cell it might be doable if cell testing can be somehow automized. As a thump of rule, it might be stated that the lower level (packàmoduleàcell) you are dealing with the higher are the cost and the lower are the business opportunities.

If the EV battery has reached the end of its useful life and recycling and recovering the battery pack, modules or cells is not possible can valuable materials from the cells be recycled. Recycling opportunities cover extracting and reusing materials like lithium, cobalt, nickel, and other metals found in the cells. This last option is focal because it is important to reduce the reliance on virgin resources and minimize environmental impact.

The handling process for electric vehicle (EV) lithium-ion batteries to prepare them for second-life usage involves usually following steps:

- Battery Collection and Sorting: Collect used EV batteries from various sources sorting the batteries based on their condition, capacity, and other relevant factors.

- Battery Testing and Evaluation: Conduct thorough testing and evaluation of the collected batteries.

- Battery Reconfiguration and Balancing: batteries may need to be reconfigured or balanced to optimize their performance. This could involve grouping batteries with similar characteristics to create battery packs with desired capacity and voltage levels.

- Safety Measures: This includes proper handling procedures, such as wearing personal protective equipment, using appropriate storage and transportation methods, and following safety guidelines for electrical systems.

Throughout the entire process, it is crucial to adhere to safety standards and regulations to minimize risks associated with handling lithium-ion batteries. Proper training and expertise in battery handling and electrical systems are essential for ensuring the successful transition of EV batteries to their second-life usage.

This article is written as a part of the project “Developing Battery Second Life Business in Ostrobothnia” and financed by the European Union.