Ensuring the sustainability of supply chains is gradually becoming mandatory for all companies. Carbon-Neutral Society master’s degree programme at Vaasa University of Applied Sciences is challenging students to recreate more sustainable models of production and consumption. The focus of the programme is on huge issues like environmental conservation and climate change head-on. It teaches students how our actions affect the environment and equips them with skills to make a difference. The program covers a wide range of topics, from renewable energy to policy analysis, helping students understand sustainability in a practical way.

One key focus is on sustainability and circular economy principles. Students learn to rethink how we produce and consume, aiming to reduce waste and use resources more efficiently. This mindset shift is crucial for making real changes in today’s world, where economic, social, and environmental factors are all connected. The program also emphasizes leadership skills in the context of sustainability. It recognizes that making a lasting impact requires more than just knowing the facts – it’s about leading others towards a greener future. Graduates come out ready to lead organizations in making sustainable decisions, from engaging stakeholders effectively to making strategic plans that benefit society as a whole.

Petri Antila (2024) did his master´s thesis as a development task where the case was European company aiming to create a roadmap for sustainable procurement. The assignment was to identify what should be changed in the supply chain, how to change it, and how to implement the identified improvements, enabling the sustainable development of procurement.

The identification of procurement changes and the creation of a roadmap was done by using the logical thinking process (LTP) strategy and problem-solving methodology. The logical thinking process is an excellent method to improve system performance as it provides a clear goal, identifies what needs to be changed, resolves conflicts, validates future reality to achieve desired outcomes with logic, and creates action plans with built-in risk mitigation for successful execution (Dettmer, 2007). The logical thinking process methodology depends on systems knowledge and data accuracy. Getting the right knowledgeable individuals to participate in roadmap development is crucial. If the used data were invalid, the outcome would be a plan that does not reflect reality. The logical thinking process methodology enabled the creation of a concrete action plan for implementation, which was easy to convert into a project plan.

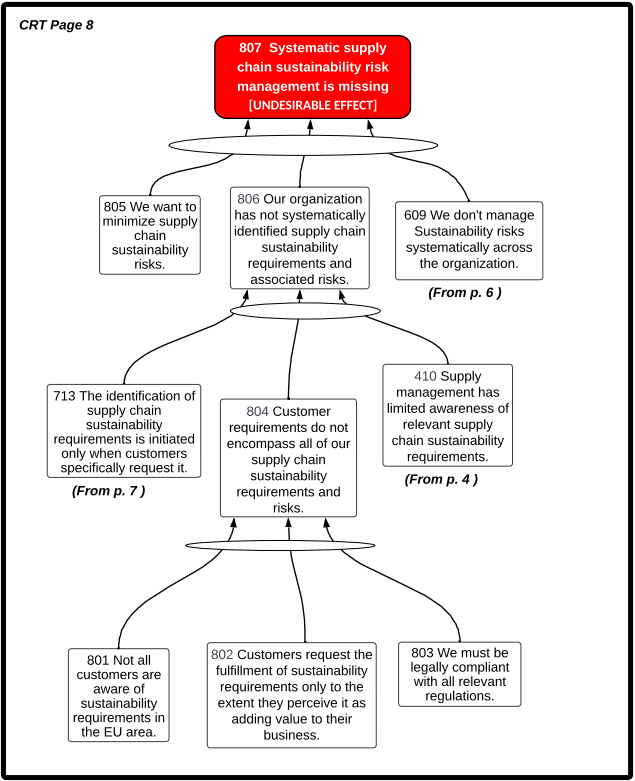

Figure 1. Current Reality Tree – Minimized Sustainability Risk (Antila 2024).

Procurement was handled as a whole with criteria defined as an enabler of deliveries. Procurement is part of the supply chain, enabling the timely flow of production with the right quality and at the right cost. Sustainable supply management requires sufficient skillset and personnel supported by a built-in information flow and the necessary policies, processes, and guidelines to enable supply chain sustainability within company sustainability requirements. Supply management is connected to almost the entire supply chain. Sustainability requirements come from legal compliance (CSRD, REACH, RoHS, etc.) and customer requirements, and complying with the aforementioned legal requirements sets the baseline for sustainability risk management. Sustainability requirements must be integrated into the supply chain. If sustainability activities are not part of the customer requirement process and are not integrated into supply chain activities, fulfilling customer sustainability requirements will not minimize sustainability risks (Figure 1) and consequential costs will remain hidden. The total cost model (TCO) can be used to support supplier management and sustainability (Ellram, 2014). By considering the total cost of ownership, all relevant costs become visible to the organization, enabling cost tracking and resource utilization. The most important factor in transforming the supply chain into a sustainable one is top management support. Without support, it is very difficult to accomplish changes due to resistance to change.

The creation of a strategic roadmap with a concrete action plan began with a desktop goal tree using a cloud-based diagramming application called Lucidchart. The initial goal tree was prepared based on the company’s public information, gathering inputs from the company’s mission, vision, and strategy to understand what the company’s goal tree would look like. This provided a better understanding of what is important in supply management towards the company’s goals and served as the starting point for the supply management goal tree with system-specific hierarchical requirements. To understand what needs to be changed, a gap analysis was conducted by comparing the current reality to the set goal and hierarchical requirements to identify deviations and critical root causes. The case company has multiple manufacturing locations in two different countries in the EU, each with a different customer base and issues at hand. In addition to this, the company has two different ERPs in use, creating additional complexity in the analysis. Due to the complexity of different manufacturing locations having different deviations compared to the goal tree and underlying requirements, the scope of the master’s thesis was adjusted to cover the total cost of ownership and sustainability risk management. With the used methodology LTP, system improvement would require all critical root causes to be solved to achieve the system goal.

Solution development was the third step in which a solution was developed for the underlying conflict of the identified critical root cause by using Evaporating Cloud (EC). The Evaporating Cloud was created with relevant stakeholders by defining wants, needs, and a common objective clarifying two sides of the conflict. Each connection’s underlying assumptions were identified and which of the assumptions were invalid. Invalid assumptions were the places to develop solutions (injections) to overcome the conflict and thus remove the critical root cause. Developed injections were the starting points for the future reality tree. The future reality tree (FRT) was the fourth step in the logical thinking process methodology. The logical thinking process defined the FRT goal as a desktop simulation in which developed injections and supporting injections are validated to ensure transformation current reality to a forward-looking future reality tree as a path to the desired outcome and system goal. Based on all created injections in the FRT, a detailed action plan was formed. Actions were defined in brainstorming sessions with individuals who have the role and knowledge to execute the change. The participants included a supply management sustainability expert, quality director, supply management director, and company CEO.

Companies striving to future-proof their supply chains should take systems view for change initiatives. Changes can easily be blocked by the existing decision-making structure if the main actors within the supply chain and customer deliveries only see the world from their own perspective. The attitude and culture of “Not my responsibility, not supporting” is not a success factor for change. Sustainability initiatives require efforts from all to enable system-level improvement.