Industrial testing and challenges

Industry plays a vital role in society’s development. Manufacturing within the industry drives economic growth and social progress. And industrial research and development (R&D) are crucial for product innovation, enhancing quality, improving efficiency, and increasing customer satisfaction. Additionally, testing serves as a guardian of industrial production and R&D, because if an error occurs, the later it was found the greater damage it could cause.

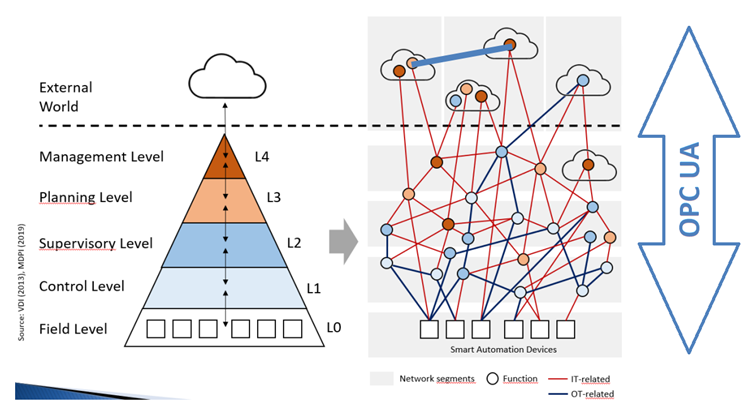

In today’s industrial automation environment, planning and developing testing procedures often involve accessing vast amounts of measurement data and configuration parameters from multiple devices. This task is complicated by the variety of protocols and communication restrictions in traditional industrial automation systems, as shown in Figure 1. Overcoming these challenges requires creating custom applications that support all necessary devices and protocols, which can be both difficult and expensive.

Industry 4.0 and OPC UA

Industry 4.0 envisions a future where manufacturers integrate smart technologies such as the Internet of Things (IoT), cloud computing, analytics, artificial intelligence, and machine learning into their operations. Achieving this vision necessitates seamless communication between devices for smarter industrial automation. In this interconnected network, measurement data and operational parameters are analyzed to facilitate better decision-making, predictive maintenance, and self-optimization of processes.

However, in the classic industry automation pyramid architecture (as depicted in the left part of Figure 2), devices can only communicate with adjacent levels. For instance, field-level devices (such as sensors and actuators) can only communicate with control-level devices (such as PLCs and CAM devices). If the management level requires data from the field level, information must be passed step by step all the way to the top level. This approach is not only inefficient but also complex and costly when developing the entire system.

OPC UA (Unified Architecture), also known as IEC62541, emerges as a key technology for advancing Industry 4.0. It provides standard communication interfaces for all levels of industrial devices and is cross-platform, supporting Windows, Linux, MacOS, Android, and even bare-metal devices. Additionally, OPC UA enhances cybersecurity through features such as encryption, authentication, and auditing, along with comprehensive data modeling to represent complex real-world devices and systems. (OPC Foundation, n.d.)

Testing solution for Industry 4.0

Wapice Ltd has developed a solution called Automatic Run (AR) to assist its customer with industrial testing. AR is a suite of applications designed to empower testing engineers in creating, executing, and monitoring tests within an industrial R&D environment. While the original AR already supports several customer protocols, the ongoing development of additional protocol support can be costly. Recognizing the potential of OPC UA technology, the customer requested an update to the original AR by developing an OPC UA extension. The outcome was Automatic Run Version 2, which includes an OPC UA client application as an extension. This project was basis for a thesis written by Siyuan Xu and supervised by Anna-Kaisa Saari. Thesis can be found from https://urn.fi/URN:NBN:fi:amk-2024060219819.

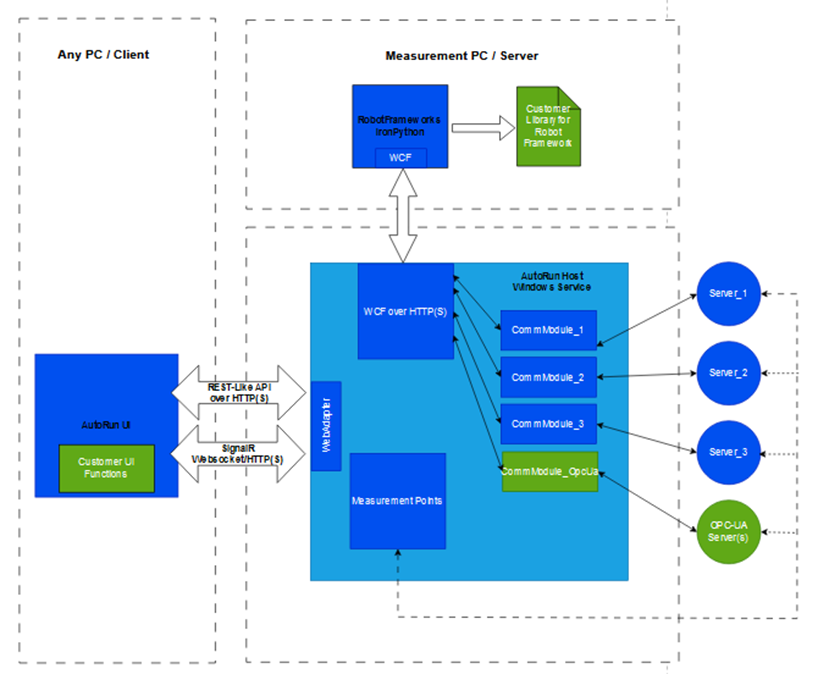

Both AR solutions, version 1 and version 2 share a common architecture, comprising three main components: Automatic Run UI (AR UI), Automatic Run Service (ARS) and Customer Keyword Library (CKL), as shown in Figure 3. The AR UI is a front-end application that allows users to create, control and monitor tests. User-created tests are serialized into Robot Framework (RF) scripts and sent to ARS for execution. The ARS serves as the core hub, connecting with various devices to access measurement point data and executing tests using Robot Framework, a well-known open-source testing software based on Python (Robot Framework, n.d.). It reports test progress and results back to the front end. The Customer Keyword Library, a Python library, provides extended functionality tailored to meet specific customer requirements.

Communication between AR UI and ARS relies on HTTP(S) for REST-like APIs and WebSocket for efficient real-time communication. Additionally, ARS communicates with Robot Framework via Windows Communication Foundation (WCF), an inter-process communication protocol developed by Microsoft for Windows OS. WCF enables ARS to control the testing processes and collect test results.

Conclusion

The AR Version 2 solution meets the customer’s requirements by integrating the OPC UA extension. It supports connections to up to five OPC UA servers and can handle millions of data nodes during testing. The AR UI and Customer Keyword Library were updated to incorporate the new functions introduced by OPC UA extension. With AR Version 2 and OPC UA, testing engineers can now access data from all OPC UA-enabled devices across various automation levels, enabling them to create, execute, and monitor tests effectively within their R&D environment.