Introduction

Finland is exploring green hydrogen as a potential solution to reduce fossil fuel dependency and meet its ambitious carbon neutrality targets. However, realizing a green hydrogen economy presents various challenges related to costs, infrastructure, and policy support. As part of Finland’s commitment to renewable energy, green hydrogen has gained attention for its potential role in achieving the country’s climate goals (IEA I., 2019). Finland’s abundant renewable resources provide a solid foundation, yet the journey toward establishing a hydrogen-based economy is complex, requiring extensive investment, strategic policy support, and technological advancements (Rytkönen, 2023). This article delves into a literature review, cost analysis, and case study insights to evaluate the feasibility of Finland’s green hydrogen transition.

Literature Review

Global, European and Finnish Hydrogen Strategies

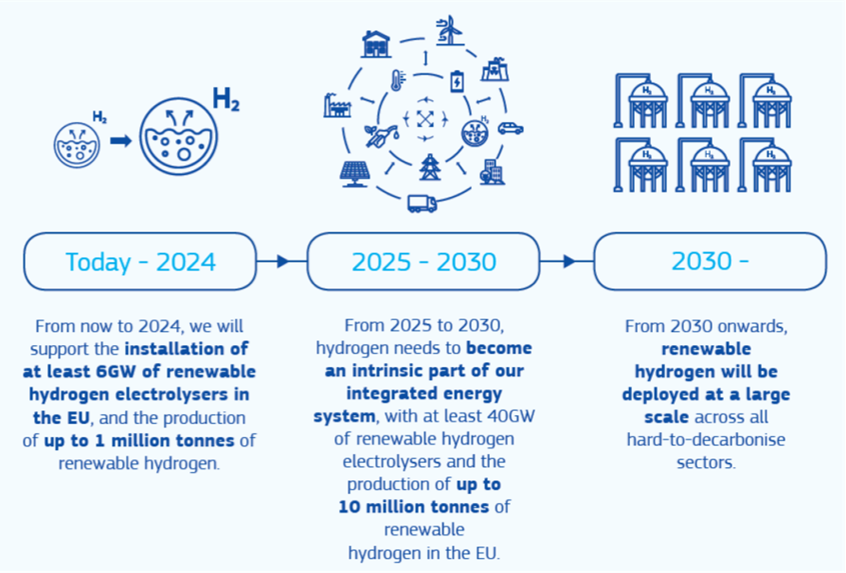

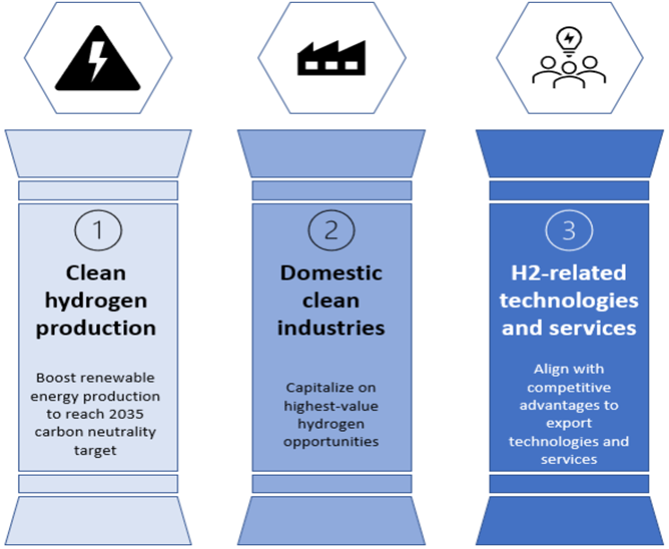

Green hydrogen plays a central role in global decarbonization, with the EU aiming to produce and import 20 million tons by 2030 and expand electrolyzer capacity to 40 GW by 2050, as shown in Figure 1 (Sharma, 2022). Finland, targeting carbon neutrality by 2035, launched its own hydrogen program in 2020 to align with EU goals, strengthen energy security, and position itself as a leader in hydrogen production by 2035 (Ministry of Economic Affairs and Employment in Fin, 2024) (IEA I., 2023). Finland’s strategy builds on its renewable energy strengths—wind, bioenergy, and hydropower, which made up over 43% of its energy mix in 2021—and includes plans to establish hydrogen “valleys” for collaboration on infrastructure, research, and investment, as seen in Figure 2 (H2 Cluster Finland, 2023). (IEA I., 2023) (Ministry of Economic Affairs and Employment in Fin, 2024).

Overview of Green Hydrogen Production Technologies

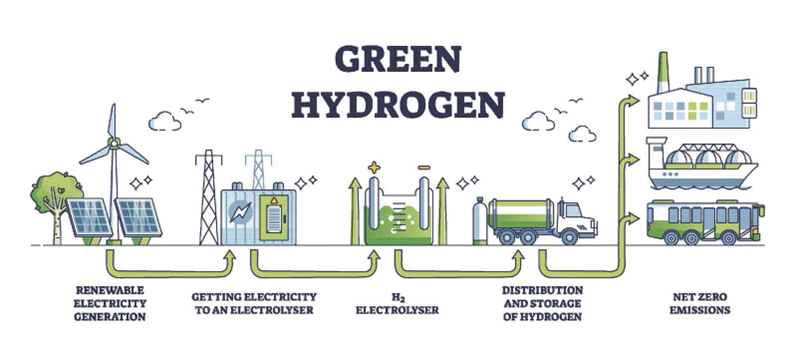

Green hydrogen, produced using renewable energy for near-zero emissions (see Figure 3), primarily relies on electrolysis to split water into hydrogen and oxygen. This process typically uses PEM (Proton Exchange Membrane) and AEL (Alkaline Electrolysis) technologies. While PEM is more efficient and compact, it is costlier than AEL, as shown in Table 1 (Gandía, Arzamendi, & Diéguez, 2013) (Sharma, 2022). The Solid Oxide Electrolysis Cell (SOEC) is an emerging option that uses high temperatures to enhance energy efficiency by reducing electricity consumption per kilogram of hydrogen (Gandía, Arzamendi, & Diéguez, 2013).

| Characteristics | AEL | PEM | SOEC |

|---|---|---|---|

| Operation parameters | |||

| Temperature (℃) | 40-90 | 20-100 | 650-1000 |

| Pressure (bar) | < 30 | <200 | <20 |

| Current Density (A/cm2) | 0.20-0.40 | 0.60-2.00 | 0.30-2.00 |

| Voltage (V) | 1.80-2.40 | 1.80-2.20 | 0.70-1.50 |

| Nominal Features | |||

| Cell area (m2) | <4 | <0.13 | <0.06 |

| Production rate (m3/h) | <1400 | <400 | <10 |

| Gas purity (%) | >99.50 | >99.99 | >99.90 |

| System Details | |||

| Energy-consumption (kWh/m3) | ~5.55 | ~5.40 | ~3.80 |

| Efficiency (%) | 51-60 | 46-60 | 76-81 |

| Stack lifetime (kh) | 60-120 | 60-100 | 8-20 |

| Degradation (%/y) | 0.25-1.50 | 0.50-2.50 | 3-50 |

| Economic Parameter | |||

| Capital costs (EUR/kWh) | 740-1390 | 1300-2140 | >2000 |

| Maintenance cost (% investment/year) | 2-3 | 3-5 | Not available |

| Maturity | Commercial | Near Commercial | Demonstration |

Cost analysis

Capital Expenditures (CAPEX) and Operating Expenses (OPEX)

The cost of green hydrogen production is a critical factor influencing its feasibility in Finland. Green hydrogen production incurs high capital expenditures (CAPEX), primarily driven by the cost of electrolyzers, Balance of Plant (BoP) components, and the infrastructure required for renewable energy sources. For instance, PEM electrolyzers, entail an approximate cost of €600/kW, while BoP components add an additional 30-50% to the total CAPEX (Laurikko, Ihonen, Himanen, & Kiviaho, 2020). The costs associated with hydrogen storage, compression, and transportation infrastructure also contribute significantly to overall CAPEX, making green hydrogen currently less competitive than conventional fuels (IRENA, 2019).

Operating expenses (OPEX), which include electricity costs, labor, and maintenance, represent another substantial cost factor. Finland’s average electricity cost is around €0.059/kWh, making electricity the single largest operating expense, given that PEM electrolyzers consume roughly 50 kWh of electricity to produce 1 kg of hydrogen (Eurostat, 2024). Additionally, maintenance costs for electrolyzers are estimated at 2-5% of total CAPEX annually, highlighting the need for efficient and cost-effective technologies to reduce overall expenses (IRENA, 2019).

Electricity Cost and Production Feasibility

The feasibility of green hydrogen in Finland is closely tied to the cost of electricity. As electrolysis is energy-intensive, electricity prices greatly impact production costs. At the current electricity rate of €0.059/kWh, producing 1 kg of hydrogen via PEM electrolysis incurs an electricity cost of approximately €3, making it challenging for green hydrogen to compete with traditional fuels without governmental subsidies (Eurostat, 2024). For green hydrogen to become economically viable, Finland may need to introduce subsidies or lower electricity tariffs specifically for hydrogen production, as suggested by industry experts (Rulison, 2023).

Long-term Cost-Competitiveness and Technological Advancements

While advances in technology and economies of scale are expected to reduce green hydrogen costs. Innovations like SOEC, which uses heat to cut electricity requirements, may further lower costs. With large-scale production and cheaper renewable energy, green hydrogen could achieve cost parity with fossil fuels by 2030 (Gandía, Arzamendi, & Diéguez, 2013) (IRENA, 2019).

Research Methodology

This study explored the potential of green hydrogen in Finland using a qualitative approach. Semi-structured interviews were conducted with experts in the green hydrogen sector, allowing for in-depth exploration of the topic while ensuring that the key areas were addressed. Details about the interviewees, including their roles and experience in the industry, can be found in Table 2.

| Title / Work Position in a green hydrogen production plant (May 2024) | Name | Work Experience in the Industrial Sector (5-10, 10-15, >15 years) | Work Experience in the Renewable Energy & Hydrogen Industry (<5, 5-10, years) | Date of the Interview |

|---|---|---|---|---|

| Project Director | A | >15 | <5 | 27.05.2024 |

| Project Manager | B | >15 | <5 | 31.05.2024 |

| Engineering Manager | C | 10-15 | <5 | 31.05.2024 |

| Project-Control Manager | D | 5-10 | <5 | 27.05.2024 |

Results and Analysis

The interview questions were based on five main themes, and a summary of the results is presented in Table 3 below.

| Theme | Summary of Interviewees’ Insights |

|---|---|

| Policy and Regulatory Landscape | All interviewees stressed the need for supportive policies, updated legislation, and tax incentives to attract investment, with a streamlined permitting process noted as critical. |

| Technological Aspects | Electrolysis (especially PEM, Alkaline, SOEC) identified as the main production method, with a focus on R&D for storage and renewable sources like wind and hydropower. |

| Economic Considerations | High production costs were a common concern. Government support, such as tax reliefs and subsidies, was seen as essential to improve cost-competitiveness. |

| Opportunities and Challenges | Interviewees saw economic growth potential and reduced fossil fuel dependency as major benefits, while infrastructure and cost barriers remain significant. |

| Required Development | Investment in renewable energy, infrastructure, and a stable political framework are needed, along with strategic planning for an export market. |

Conclusion and Recommendations

Transitioning to a green hydrogen economy in Finland is feasible but requires addressing key challenges. Green hydrogen holds significant potential as a sustainable energy source in Finland, supported by ample renewable resources, progressive policies, and economic opportunities. However, high production costs, extensive infrastructure needs, and the requirement for technological advancements pose considerable obstacles. Addressing these challenges through strategic investments, policy support, and innovation will be crucial to achieving a viable hydrogen economy in Finland. The recommendations for accelerating green hydrogen adoption include:

Policy and Regulatory Measures

- Implement clear, predictable policies and provide targeted subsidies and tax incentives to support green hydrogen. Address regulatory uncertainties to foster investor confidence and streamline permitting processes.

Stakeholder Engagement

- Encourage collaboration among industry, government, and research institutions to drive innovation. Launch public awareness campaigns and engage local communities to ensure an inclusive transition to green hydrogen.

Investment in Infrastructure

- Increase funding for renewable energy, grid infrastructure, and pilot projects like hydrogen valleys. These investments are crucial to lowering production costs, improving efficiency, and accelerating deployment.

Technological Advancement and Research

- Invest in research to enhance electrolysis efficiency and explore alternative production methods. Developing advanced storage solutions is also essential to address hydrogen’s low energy density and improve distribution.